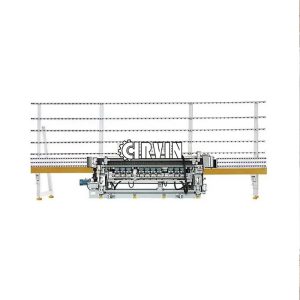

10 motor glass beveling machine ABB motor low cost

This machine is designed for producing bevel edge, with bottom edge grinding. The conveyors pads use reinforced steel sheets, which are treated under special process and have high rigidity. The glass transmittance is very smooth. spindles are directly driven by high precision ABB motor. The working speed is adjustable by stepless regulator. The glass thickness and working speed are shown on digital readout. This machine is featured by high efficiency and precision easy operation and low cost.

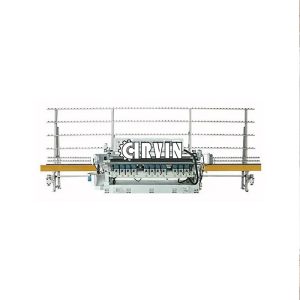

11 12 motors ball bearing glass beveling machine PLC controller

This machine is specially designed for making bevel on small glass (30x30mm) and big glass(3mx3m), it can also make 45 degree bevel edge. The front conveyor track can be moved up and down according to glass size. This machine adopt PLC control and operator interface. The Screen can show glass thickness, bevel angle, bevel width and back track height. Front and back Conveyors use ball bearing conveyor, the drive gear directly drive the roller of each pad.

11 motor manual glass beveler with digital speed easy operation

This machine is designed for producing bevel edge, with bottom edge grinding. The conveyors use short-joint big roller chain system. Grinding wheel are directly driven by high precision ABB motor. The working speed is adjustable by stepless regulator. The front rail is driven by motor for adapting to various glass thickness. The glass thickness and working speed are shown on digital readout. This machine is featured by high efficiency and precision, stable quality, easy operation and low wear.

11 motor PLC glass beveler most popular in China

This machine is designed for producing bevel edge, with bottom edge grinding. The machine adopts PLC control and operator interface. All the data can be input through working panel. The conveyors use short-joint big roller chain system. Grinding spindles are directly driven by high precision ABB motor. This machine has a high automatization. It is featured by high efficiency and precision, stable quality, easy operation and low wear.

12 motors Italian ball bearing beveling machine PLC computer

This glass beveling machine use ball bearing conveyor system. It is the very precise and move very stable and steady. All the bearing use NSK produced in Japan. The back conveyor of this machine can raise/lower to work different size glass. It is PLC controlled, with touch panel working system. screen show angle, bevel Width, bottom thickness, it is easy to operate. The machine use ABB spindle, speed inverter system. It has high working efficiency and precision.

9 motor glass beveling machine ABB motor low cost

This machine is designed for producing bevel edge, with bottom edge grinding. The conveyors pads use reinforced steel sheets, which are treated under special process and have high rigidity. The glass transmittance is very smooth. Spindles are directly driven by high precision ABB motor. The working speed is adjustable by stepless regulator. The glass thickness and working speed are shown on digital readout. This machine is featured by high efficiency and precision easy operation and low cost.

9 motor glass beveling machine, PLC control& touch screen

This machine is used for making bevel on glass and mirror, with a peripheral diamond wheel grinding the bottom edge. This machine adopt PLC control and operator interface. The bevel width and angle can be set through PLC very accurately. The pneumatic polishing wheels make the bevel very shining Basement and frame are made of cast iron to ensure stability and solidity Conveyors use chain transmitting system which consist of anti-friction rubber griping pads with reinforced sheet steel bone. This structure guarantee glass is stably moved. The working precision is high. Working speed is adjustable through speed regulator.

9 motor small glass beveling machine PLC control ZX261D 361D 371D

This machine is designed to make bevel on both small glass and big glass. The back conveyor track can be moved up and down according to glass size. For small glass size, the back conveyor track can be moved upward. For big glass size, the back conveyor track can be moved downward, it adopt PLC control and operator interface. The Screen can show glass thickness, bevel angle, bevel width and back track height. Conveyors use big roller chain transmitting system, glass griping pads has design for working small glass, it is changeable after wear off. This structure guarantee glass is stably moved. The working precision is high.

arvinglass.ir

arvinglass.ir