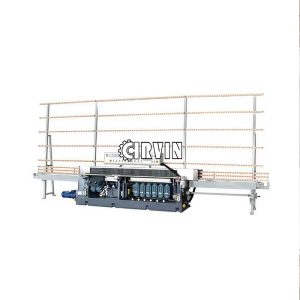

6 motors round edge OG edge most popular glass machine

این دستگاه می تواند لبه گرد، لبه OG و سایر لبه های پروفیل را روی شیشه تخت تولید کند. نوار نقاله جلویی را می توان به صورت موازی حرکت داد تا با ضخامت های مختلف شیشه سازگار شود. دو چرخ درز جلویی می توانند شیشه های شیشه ای را حذف کنند، که کار چرخ های جانبی عقب را کاهش می دهد، طول عمر چرخ های محیطی را افزایش می دهد و سرعت کار را افزایش می دهد.

9 motor glass beveling machine ABB motor low cost

This machine is designed for producing bevel edge, with bottom edge grinding. The conveyors pads use reinforced steel sheets, which are treated under special process and have high rigidity. The glass transmittance is very smooth. Spindles are directly driven by high precision ABB motor. The working speed is adjustable by stepless regulator. The glass thickness and working speed are shown on digital readout. This machine is featured by high efficiency and precision easy operation and low cost.

9 motor glass beveling machine, PLC control& touch screen

This machine is used for making bevel on glass and mirror, with a peripheral diamond wheel grinding the bottom edge. This machine adopt PLC control and operator interface. The bevel width and angle can be set through PLC very accurately. The pneumatic polishing wheels make the bevel very shining Basement and frame are made of cast iron to ensure stability and solidity Conveyors use chain transmitting system which consist of anti-friction rubber griping pads with reinforced sheet steel bone. This structure guarantee glass is stably moved. The working precision is high. Working speed is adjustable through speed regulator.

9 motor small glass beveling machine PLC control ZX261D 361D 371D

This machine is designed to make bevel on both small glass and big glass. The back conveyor track can be moved up and down according to glass size. For small glass size, the back conveyor track can be moved upward. For big glass size, the back conveyor track can be moved downward, it adopt PLC control and operator interface. The Screen can show glass thickness, bevel angle, bevel width and back track height. Conveyors use big roller chain transmitting system, glass griping pads has design for working small glass, it is changeable after wear off. This structure guarantee glass is stably moved. The working precision is high.

9 motors glass edging machine most popular chain system

The machine performs bottom edge grinding/polishing on flat glass, with arris polishing. Conveyor adopts chain transmitting system consisting of special stretchy rubber pad. Front rail can be moved in parallel to adapt to different glass thickness. Working speed is adjustable through speed regulator. The arris spindles adopt drag plates structure, no vibration in working. This machine is easy to operate and has good performance. The last wheel can be a independent felt polishing wheel or rubber wheel.

automatic accurate drilling machine line with PLC and Servo system

این دستگاه حفاری شیشه را می توان با دستگاه لبه دوبل متصل کرد تا یک خط اتوماتیک ایجاد کند. می تواند به طور مستقل نیز کار کند.

automatic ball bearing ABB motor glass edging polishing machine

The machine performs bottom edge grinding/ polishing on flat glass, with arris grinding. Conveyor adopt ball bearing transmitting system, which consists of three bearings rolling along high precision tempered steel guides, the movement of glass is very stable. Control system adopt Mitsubishi PLC control unit, which has automatic and manual control functions, The main working parameters are set and displayed through an operator interface. Working speed is electronically adjustable. Spindles are driven by high quality ABB motors.

automatical chain system variable angle glass edging mitering machine

This machine can do normal flat edge polishing, it can also make miter edge of 0-45 degree. This machine use PLC control and touch panel operating system. The machine can run in automatic mode and manual mode. The front 4-6 motors can adjust angle from 0 degree to 45 degree for polishing bottom edge and miter edge.

chain system automatic glass flat edge polishing machine puenmatic

This machine use PLC control and touch panel operating system. It perform flat edge polishing, the pneumatic polishing system makes the machine more friendly for operation, the glass finish is super ideal. The machine can run in automatic mode and manual mode. Conveyor use chain transmitting system, working speed is adjustable through speed regulator.

double edger flat edgers full automatic

این لبه دوبل می تواند دو لبه صاف شیشه را به طور همزمان آسیاب/براق کند. این دستگاه کنترل PLC و رابط اپراتور را اتخاذ می کند. بخش سنگ زنی متحرک در امتداد راهنمای بلبرینگ دوقلو خطی حرکت می کند. انتقال از طریق پیچ های سرب بلبرینگ دوقلو انجام می شود که توسط موتور با شکستگی هدایت می شود. بالا و پایین رفتن سیستم ردیابی بالا و موتورهای آریس بالایی توسط موتورها هدایت می شود. می توان آن را به طور خودکار با توجه به ورودی ضخامت شیشه های مختلف تنظیم کرد.

double edging line high speed super glass finish T transfer table

این خط تولید از یک میز اندازه گیری اندازه شیشه هوشمند، دو لبه دوتایی و یک میز انتقال L شکل تشکیل شده است. این پورت برای اتصال میز اندازه گیری با سیستم ERP و سیستم اسکن برای تسهیل نیاز تولید خودکار موجود است. میز اندازه گیری شیشه ای برای انتقال و قرار دادن شیشه مورد پردازش، اندازه گیری دقیق طول، عرض و ضخامت شیشه و انتقال داده ها به آسیاب دو لبه و سایر تجهیزات پردازش برای پردازش بیشتر شیشه استفاده می شود.

economic small size glass edging machine rough finish

The machine is designed for grinding bottom edge of flat glass, with arris grinding. It is suitable for rough processing before tempering and the other further processing. Conveyor adopts chain transmitting system consisting of special stretchy rubber pad.

arvinglass.ir

arvinglass.ir